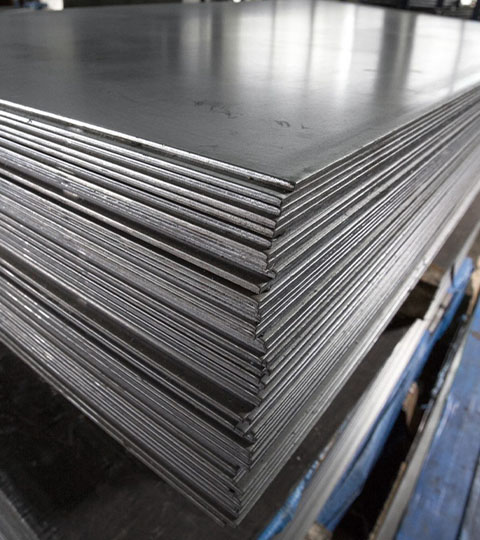

Stainless Steel Sheets

Stainless Steel 304

A High-Performance Alloy Steel

Stainless Steel 304 is one of the most notable types of Alloy Stainless Steels, also known as 304 non-magnetic Stainless Steel. Due to its unique properties, this type of Steel is highly popular in various industries. The key characteristics of Stainless Steel 304 include high corrosion resistance, excellent machinability, and good tensile properties. These features make 304 Stainless Steel an ideal choice for industrial and construction applications where durability and high performance are crucial.

Advantages of Using Stainless Steel in Architecture

Stainless Steel 304 plays a crucial role in modern architecture due to its high durability and aesthetic appeal. The advantages of using stainless Steel in architectural applications include:

High durability and longevity due to corrosion resistance

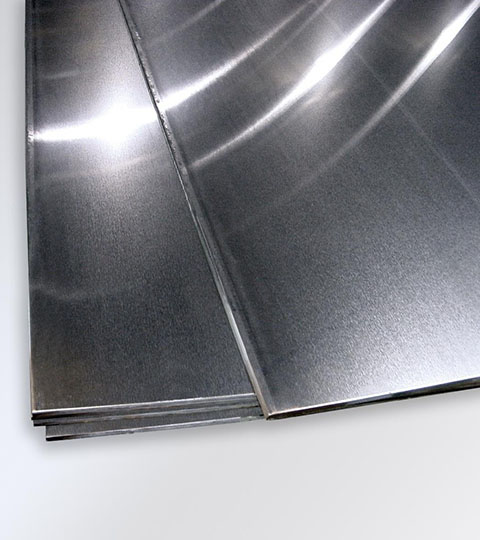

Attractive and visually appealing surface

Easy and quick cleaning capability

Flexibility in shaping and designing structures

Adaptability to various construction styles

Excellent resistance to environmental changes

High usability in humid regions

Stainless Steel 304L

A Corrosion-Resistant and Versatile Alloy

Stainless Steel 304L is a low-carbon version of 304 Stainless Steel, classified as an austenitic chromium-nickel Alloy. It is widely used due to its outstanding properties and is available in various thicknesses, sizes, and surface finishes. This Alloy finds extensive applications in industries such as construction, automotive, and household appliances due to its superior corrosion resistance and mechanical properties.

Key Benefits of Stainless Steel 304L:

Low carbon content prevents carbide precipitation during welding

No need for post-weld annealing

Excellent performance in highly corrosive environments

Stainless Steel 316

A Unique Alloy for Harsh Conditions

Stainless Steel 316 is a corrosion-resistant alloy widely used in demanding environments. In German DIN standards, it is referred to as Steel 1.4401 and is known by its designation X5CrNiMo17-12-2. This non-magnetic Stainless Steel, commonly called 316 non-magnetic Stainless Steel, does not get attracted to magnets. It is particularly resistant to corrosion and rust, especially in chloride-rich environments, making it ideal for marine, chemical, and food industries.

Applications of Stainless Steel 316:

Heat exchangers

Food processing equipment, especially in chloride environments

Coastal architectural panels

Railing systems

Wire mesh and filtration components

Laboratory benches and equipment

Boat fittings

Chemical storage and transportation tanks

Stainless Steel 316L

A High-Performance Stainless Alloy

Stainless Steel 316L is a low-carbon version of 316, widely used in industrial and construction applications. It is extensively used for manufacturing valves, fittings, pipes, bars, profiles, channels, and angles. Additionally, it is used in producing Stainless Steel flanges, sheets, tubes, and strips. Due to its exceptional resistance to corrosion and rust, particularly in corrosive environments, Stainless Steel 316L is an ideal choice for applications requiring high durability and strength.

Applications of Stainless Steel 316L:

This grade is widely used in pressure vessels, medical equipment, shipbuilding, seawater-exposed environments, heat exchangers, food processing industries, and medical instruments.

Stainless Steel 430

Corrosion Resistance and Good Formability

Stainless Steel 430, or 1.4016, is a ferritic Stainless Steel alloy with remarkable properties. It exhibits excellent corrosion resistance and good formability, along with resistance to nitric acid. Since Stainless Steel 430 cannot be hardened through heat treatment, it is particularly useful in the chemical industry and applications requiring good corrosion resistance and shaping capabilities.

Applications of Stainless Steel 430:

Inner casing of dishwashers

Refrigerator liners

Structural supports and brackets

Stove bodies

Chimney pipes

Properties of Stainless Steel 430:

Excellent resistance to stress corrosion cracking

Good resistance to organic acids and nitric acid

Maximum corrosion resistance when polished